Heat and mass transfer take place in almost all energy and process engineering applications and significantly determine their mode of operation and efficiency. Against the backdrop of climate change and increasing demands for efficiency and environmental compatibility, heat and mass transfer is becoming increasingly important.

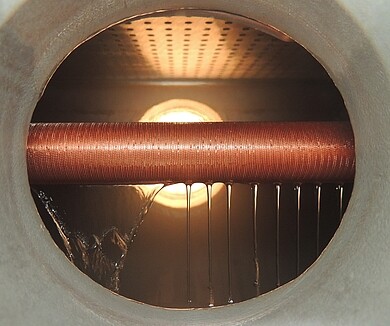

©

IfT, Leibniz Universität Hannover

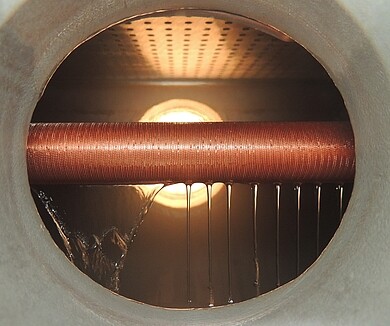

©

IfT, Leibniz Universität Hannover

At the institute, research work is carried out that addresses both basic research and industrial applications. The focus of the work at the institute is the experimental investigation and modeling of heat transfer coefficients in classically manufactured shell-and-tube and plate heat exchangers and, more recently, in additively manufactured heat exchangers.

This includes single-phase heat transfers at low and high temperatures up to 900°C as well as two-phase heat transfers during evaporation and condensation. Against the background of phase change, refrigerants in particular are tested for their suitability in cycles and especially in heat exchangers, since legal regulations to reduce greenhouse gas emissions mean that conventional refrigerants are being replaced by newly developed refrigerants or refrigerant mixtures.

In the field of mass transfer, the institute is conducting investigations on, among other things, water-ammonia mass pairings to determine their influence on the efficiency of hybrid heat pumps. The combination of increased demands on the efficiency of heat exchangers and the use of new refrigerants and refrigerant mixtures results in a variety of research opportunities, which are addressed at the institute through individual approaches.

Competences

- Experimental determination of single-phase and two-phase heat transfer coefficients and pressure losses

- Characterization of heat exchangers

- Analysis and calculation of complex thermal systems

- Data analysis and modeling of the physical relationships