Heat exchangers are among the most widely used devices in the process engineering industry. Until now, the design of heat exchangers was determined and limited by the available semi-finished products, such as tubes or stamped plates, and by the associated conventional manufacturing processes.

Additive manufacturing now offers the opportunity to develop completely new and application-optimized apparatus concepts and heat exchanger types. As part of this development, for example, improved flow guidance and, in particular, optimized internal structures will be used. These new and more complex geometries and structures require new approaches both in terms of generation and for their thermal-hydraulic design. They cannot be effectively created using conventional design programs, nor are there correlations for determining heat transfer and pressure loss.

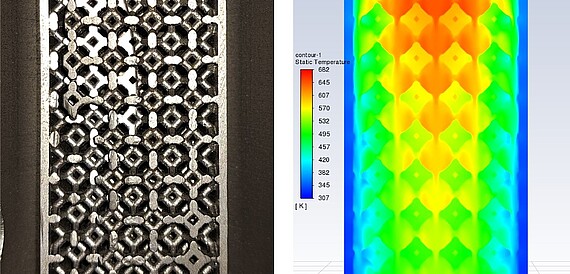

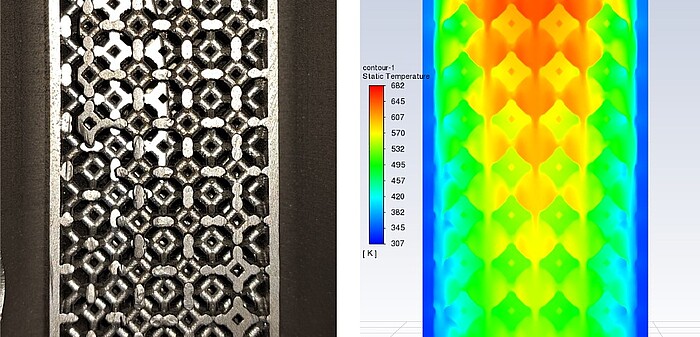

As part of this research project, in cooperation with the IPeG, lattice-shaped internal structures, so-called lattice structures, which can be produced additively using laser beam melting, are generated, manufactured and investigated using CFD simulations and experimental characterization with regard to their thermofluid-dynamic operating behaviour. Particular attention is paid to heat transfer, temperature distribution, flow and pressure loss.

30823 Garbsen